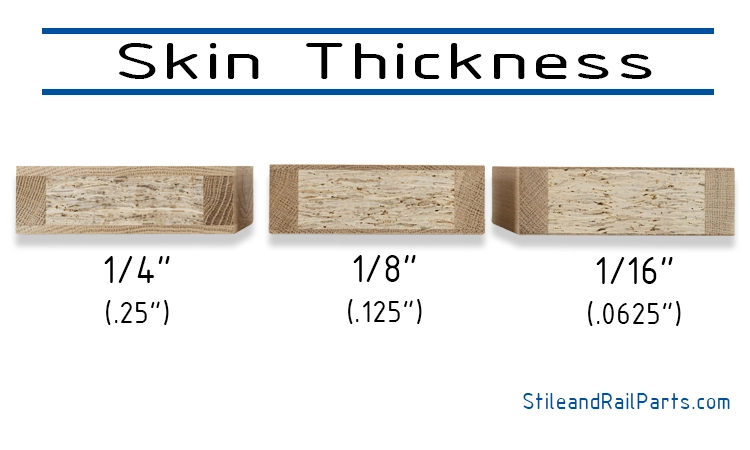

In the context of door stile and rail parts, “skin thickness” refers to the wood thickness that is applied to the core, specifically the visible portion of wood that forms the outermost layer of a wood door component. This guide explores the importance of skin thickness and how it affects stability, aesthetics and cost.

Why is Wood Skin Thickness important?

Stability

Interestingly, when it comes to stability, often the thinner the piece of wood equals an increase in stability of the component overall. This is true due to the fact that certain wood types, like white oak or maple, have a high susceptibility to splitting and cracking when exposed to harsh conditions such as low humidity.

If you’d like to take a deep dive into the “Why?” regarding wood movement and the difference from one species to the next, check out our friends at ESL Hardwood Floors. They have a nice short post that explains this well. Or simply Google: “Dimensional Change Coefficient”, and you’ll get a ton of information that quite honestly is more in depth than this post allows.

In short, to ensure the longevity and performance of wood doors, especially when working with these wood types, it’s advisable to opt for thinner skin thicknesses, typically 1/8″ (.125) or 1/16″ (.0625). This not only enhances stability but also mitigates the risk of warping or twisting, ensuring that your wood doors stand the test of time.

Aesthetic Enhancement

When it comes to the aesthetics of wood doors, skin thickness plays a nuanced role, and it’s not a one-size-fits-all scenario. Some wood types, like knotty alder or rustic hickory, truly shine when their skin is left thicker. These woods boast deep knots and rich grain variations that achieve their full visual potential with a thicker skin. The result is a door with a more natural and rustic appeal.

Notably, woods such as alder and hickory are less prone to cracking, alleviating stability concerns. In such cases, opting for a thicker skin, typically 1/4″, can genuinely enhance the visual impact of the wood doors, emphasizing their inherent beauty and character.

Cost Considerations

In the realm of custom high-end wood door components, the dynamics of cost savings related to skin thickness differ from large-scale manufacturing. While substantial savings are often realized in scenarios where ultra-thin veneers of 1/32″ are used on a massive scale, our clientele typically operate in smaller volumes..

For our customers, the primary cost-efficiency transition lies in moving from a 1/4″-inch” to a 1/8″ skin thickness. This shift allows for more effective utilization of raw boards, optimizing resource allocation without compromising quality.

However, it’s important to note that the next step down, transitioning from a 1/8″ to a 1/16″ skin thickness, doesn’t typically result in significant cost savings. Instead, this choice is often motivated by considerations of stability. For example ordering White Oak or Maple in a 1/16″ thickness because the aesthetic appearance of these woods does not change from a 1/8″ thickness but you get a higher stability.

Climate and Humidity

When deciding upon skin thickness for your wood door components, it’s essential to take climate and humidity into account. Wood is inherently responsive to changes in moisture levels in its environment. In regions with high humidity, wood tends to absorb moisture from the air, potentially causing it to expand. Conversely, in drier climates, wood can lose moisture, leading to contraction.

In areas of the country with extremely low or high levels of humidity, the general rule of thumb is: thinner the skin the better. But each area poses it’s own unique challenges. If you have any questions regarding our products and the location that it will be used in, please don’t hesitate to Reach Out via our Contact Us page. One of our sales associates would be happy to discuss your project details.

Cracks and Splitting

to the left: A split has formed on a White Oak, LSL core stile with 1/4″ thick veneer. This was caused by low onsite humidity conditions.

Choosing a thinner skin thickness would reduce the chance of cracking.

What’s Available on StileandRailParts.com?

Our current available to buy now stock items are 1/8″ skin thickness. But we recognize that your projects may have unique requirements. That’s where our Request for Quote (RFQ) section comes into play. Here, you have the freedom to specify your preferred skin thickness, whether it’s 1/16″, 1/8″, or 1/4″.

We’re committed to tailoring our offerings to your specific needs, ensuring that you have access to the right wood door components for your projects, regardless of their size or complexity.

Ready to Move Forward?

Check out our in stock items and make your purchase now

Know the Skin Thickness You Need?

Customize your order today with our easy RFQ submission portal